Slurry pumps are crucial for efficient operation in numerous fields, including mining, construction, and wastewater treatment. These centrifugal pumps can effectively move slurry, a fluid containing abrasive particles, high viscosity, and solid contents.

When searching for a slurry pump, it’s best to stick with brands with proven track records of producing high-quality products. This article will closely examine the best slurry pump manufacturers around the globe, widely recognized for their expertise and reliable products.

Want to learn about submersible slurry pumps and their benefits? Visit DAE Pump’s website.

What is the future market of slurry pumps?

The global slurry pump market was valued at USD 1160 million in 2021. It is expected to reach USD 1246 million by 2027, expanding at a CAGR of 1.2%.

The rising need for slurry pumps in sectors like oil & gas, mining, and wastewater treatment are the primary forces propelling the expansion of this market. There has also been an emphasis on efficiency gains and cost cuts, causing slurry pumps to become increasingly popular in various sectors.

Top 7 global slurry pump manufacturers

1. DAE Pumps:

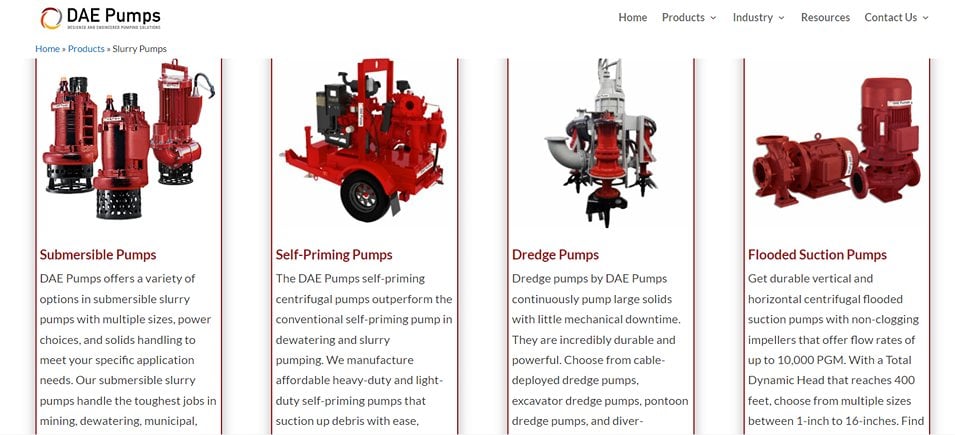

DAE Pumps offers a wide range of efficient and reliable slurry pumps for handling abrasive and corrosive materials. Our slurry pumps are built to withstand harsh conditions, providing exceptional performance and extended service life. Equipped with features like high-quality impellers, wear-resistant materials, and innovative sealing mechanisms, our pumps minimize downtime and maintenance costs.

Ideal for mining, dredging, construction, wastewater treatment, and oil and gas, our centrifugal pump excel at transporting solids-laden fluids like sand, gravel, coal, and ore. Their robust construction ensures the handling of high concentrations of solids without clogging, maximizing productivity. With versatile configurations available for different flow rates, head pressures, and motor power, our pumps cater to diverse application requirements.

At DAE Pumps, we deliver reliable solutions that enhance operational efficiency and minimize downtime. Customers can expect exceptional performance, durability, and cost-effectiveness from our slurry pumps, making them an essential choice for industries dealing with challenging materials and operating environments.

DAE Pumps

2. EDDY Pump Corporation:

EDDY Pump is one of the leading global manufacturers of slurry pumps. They specialize in handling high-density industrial fluids. The patented products are manufactured using precise engineering and durable materials. They can handle non-clog, high viscosity, high specific gravity, and abrasives slurries, with 40-70% solids pumping by volume.

3. Warman (Weir Group):

Warman, a manufacturer of slurry pumps, offers a wide variety of centrifugal pumps suitable for various uses.

Warman is a well-known manufacturer in the slurry pump industry, renowned for its durable and efficient centrifugal pump. These dredge pumps are particularly favored in sectors like mining, mineral processing, and other heavy industrial applications due to their robust construction and ability to handle abrasive materials.

However, despite their strong reputation and reliability, Warman’s range of products do show some limitations in terms of variety and versatility. The company offers a relatively limited number of product lines compared to competitors. This can be a drawback for customers looking for highly specialized solutions or pumps tailored for niche applications outside of Warman’s primary markets.

4. Metso Outotec:

Metso Outotec is recognized for providing a comprehensive range of sludge and dredge pumps, catering especially to the rigorous demands of the mining and mineral processing industries. Their centrifugal pumps are designed to handle challenging slurry pumping tasks, which involve moving mixtures of water and solids in suspension, often under tough conditions. These pumps are built to withstand abrasive and corrosive environments, making them highly suitable for applications in ore processing, tailings management, and similar heavy-duty industrial settings.

Despite their effectiveness in these demanding applications, Metso Outotec’s offerings do face some limitations in terms of design flexibility. The company’s focus is predominantly on robust, heavy-duty pumps, which means their design options are often geared towards specific, high-intensity industrial applications. This specialization can be a disadvantage for users seeking pumps for more varied or less extreme environments. For instance, industries that deal with less abrasive or mildly corrosive materials might find the pump features overly robust and not as cost-effective for their needs.

Furthermore, the lack of broader design options could restrict Metso Outotec’s pumps from being suitable for applications where different pump configurations or materials are necessary to optimize performance and efficiency. Industries such as water treatment, food processing, or certain chemical sectors might require pumps with different operational characteristics, such as lower flow rates, different impeller designs, or materials that are compliant with food-grade standards.

In essence, while Metso Outotec excels in delivering high-performance sludge and dredge pumps for mining and mineral processing, the limited variability in pump designs might not be optimal for industries requiring a more diverse range of pumping solutions. This could compel potential users to explore other manufacturers that offer a wider array of design options catering to a broader spectrum of industrial applications.

5. Flowserve:

Flowserve is a prominent manufacturer in the pump industry, known for its broad spectrum of pumping solutions tailored to meet the diverse needs of multiple sectors. Their product lineup includes centrifugal pumps, which are widely utilized across industries such as oil and gas, water treatment, and mining due to their efficiency in moving fluids through a rotational motion facilitated by one or more impellers. Additionally, Flowserve provides positive displacement pumps, favored for applications requiring precise volume management, delivering a constant amount of fluid with each mechanical cycle, making them ideal for handling viscous fluids or when pressure conditions vary.

The company also specializes in submersible pumps, which are essential for pumping fluids from deep water sources or submerged applications, ensuring durability and effective operation in fully submerged conditions. Furthermore, Flowserve’s Vertical Turbine Pumps are specifically engineered for deep water extraction processes, offering a robust design capable of operating efficiently in lower submergence conditions compared to other pump types.

6. Xylem:

Xylem is recognized globally as a supplier of slurry pumps and associated water technologies, with a strong emphasis on innovation and sustainability. Their centrifugal pumps are engineered to be resistant to wear and corrosion, attributes that are essential for handling abrasive slurries typically found in harsh industrial environments. These pumps are designed to move slurry, which consists of solid particles suspended in liquid, efficiently and effectively, ensuring optimal performance under demanding conditions. The durability and robust construction of Xylem’s pumps make them ideal for sectors where the movement of aggressive media is a routine requirement.

The use of Xylem’s slurry pump extends across various industries, including mining, mineral processing, and wastewater treatment within the manufacturing sector. These pumps are integral in applications such as ore processing, tailings management, and the treatment of industrial effluents, where the reliability and efficiency of the pumping system directly impact operational productivity and environmental compliance.

However, the specialization of Xylem’s centrifugal pumps also means that they are optimized for specific types of tasks that involve abrasive or corrosive materials. This focus on specialized applications limits their suitability for broader or less intense pumping needs, where different pump types or configurations might be more appropriate. As such, while Xylem’s pumps excel in their designed roles, their application scope might not cover all potential industrial needs, particularly in environments where the material characteristics or operational demands differ from those anticipated by their specialized designs.

7. Cornell Pump Company:

Cornell Pump provides a variety of pumps, including flooded suction pumps that can withstand and is effectively in pumping slurry.

Mining, farming, and manufacturing are where these pumps are used. But when it comes to their slurry pumps’ capacity, and technological strength for pumping abrasive slurries and solid particles, they don’t meet the customer requirements. Also, Cornell lacks the offerings when it comes to their rental pumps.

Select the most efficient slurry pump

DAE Pumps is one of the world’s best slurry pump manufacturers. Its advanced technology, state-of-the-art R&D establishment, continuous improvement, and passion for delivering the best to its customers make it the best choice.

If you require a centrifugal pump for application in construction, mining, chemical, oil & gas, pulp and paper, sewage treatment, and/or marine industries, email DAE pump or call us at (760)-477-4224. Request a free sales quote, and our team will connect with you.

Key takeaways

Slurry pumps are essential for running factory operations efficiently. The renowned slurry pump manufacturers listed above, including DAE Pumps, Xylem, etc., have established themselves as reliable providers of high-quality slurry pumps.

Products of these industrial sludge pump manufacturers are designed to handle abrasive slurries efficiently, offering durability, efficiency, and low maintenance requirements. Choosing centrifugal slurry pumps from these reputable manufacturers ensures smooth operations and increased productivity in your industry-specific applications.

Frequently asked questions about slurry pump manufacturers

1: What is a slurry pump?

A slurry pump is a type of centrifugal pump specifically designed for handling abrasive and viscous fluids known as slurries. Slurries are mixtures of solid particles suspended in a liquid medium. These pumps are widely used in industries such as mining, construction, oil and gas, and wastewater treatment, where the transfer of slurry is necessary.

2: What are the different types of slurry pumps?

Some common types of slurry pumps include:

- Horizontal Centrifugal Slurry Pump

- Vertical Centrifugal Slurry Pump

- Submersible Slurry Pump

- Slurry Pump with Shaft Seal

- Slurry Pump with Agitator

3: What are the benefits of using a slurry pump?

Using a slurry pump offers several benefits in industries where the handling and transportation of slurries are necessary. Some key benefits are efficient handling of slurries, improved productivity, reduced equipment wear, customization options, enhanced safety, and environmental considerations. These advantages make them indispensable in industries where the reliable and efficient transportation of abrasive fluids is essential.

.

4: What are the limitations of using a slurry pump?

While slurry pumps offer numerous benefits, they also have certain limitations that should be considered. These include:

- High wear and maintenance

- Clogging and blockages

- Limited efficiency with varying slurry characteristics

- Comparatively higher energy consumption

- Higher noise and vibrations as compared to centrifugal pumps

5: How do I choose the right slurry pump for my needs?

Slurry pump selection depends on the slurry’s particle size, abrasiveness, flow rate, head pressure, installation requirements, and environmental conditions. Choosing the right slurry pump for your specific needs requires you to:

- Understand Your Application

- Evaluate Pump Performance

- Consider Pump Construction and Materials

- Assess pump design and features

- Consider manufacturer reputation and support

- Seek expert advice from a slurry pump supplier

- Cost considerations

6: How do I maintain a slurry pump?

Proper maintenance is crucial for optimal performance. Conduct regular inspections, replace worn parts, and ensure proper lubrication. In addition, clean the impeller, monitor the seal condition, and flush the pump and piping periodically. It is crucial to keep records of maintenance activities and seek professional servicing when needed.

7: What is the difference between a slurry pump and a mud pump?

These two pumps are both used to handle thick, viscous fluids, but they differ primarily in their applications and construction. They are designed to handle a mixture of solids and liquids, typically in mining, dredging, and other industrial settings. They are built to withstand abrasion from particles like sand, gravel, and ore, and can also handle a wider range of particle sizes and higher concentrations of solids. Mud pumps, on the other hand, are typically used in the oil drilling industry to circulate drilling mud, which is required to cool and lubricate the drill head, and to carry drill cuttings to the surface. They are specifically designed to handle viscous fluids with fewer solid contents.

8: How Does a Centrifugal Slurry Pump Work?

A centrifugal pump operates on the principle of centrifugal force to transport abrasive, solid-laden fluids. The process begins when the slurry enters the pump impeller along the rotational axis through the suction pipe. The impeller, driven by a motor, rotates at high speed, imparting kinetic energy to the slurry. This action converts the kinetic energy into hydrodynamic energy as the slurry is forced radially outward into a diffuser or volute chamber. The design of the chamber helps convert the velocity of the slurry into pressure, efficiently directing the slurry to the discharge point. This type of centrifugal pump is especially effective for handling abrasive materials in mining, dredging, and industrial processes due to its robust construction and dynamic operation.