The mining industry is a crucial sector that extracts valuable minerals and resources from the earth. However, mining operations often face significant challenges like excess water accumulation in excavation sites, underground mines, and open pits. Mining dewatering pumps play a pivotal role in maintaining safe and efficient mining operations. These specialized pumps effectively remove water from mining areas, ensuring a dry and stable working environment.

In this article, we will dive into the importance of dewatering pumps for mining industry, their functionality, types, benefits, and their impact on environmental sustainability.

To know more about industrial dewatering pumps for mining industry, read our blogs on pumps for mining applications.

Dewatering pump in action

Table of contents

-

-

- Importance of dewatering pumps for mining industry

- Dewatering pumps for mining industry: functionality and types

- Advantages of using dewatering pumps in mining Sites

- Why Are Dae Pumps the Best Solution to Mining Dewatering?

- Final Words

- Frequently Asked Questions (FAQs) about Dewatering Pumps in Mining

-

Importance of Dewatering Pumps for Mining Industry

Mining activities involve excavating and processing ores and minerals, often requiring working in wet environments. Miners often face challenges like reduced productivity, safety concerns, and potential equipment damage. These conditions become worse when water accumulates in mines. Dewatering, or the removal of excess water from mining sites, is crucial for dealing with these complications. In mining processes, dewatering is a continuous process to keep the work ongoing and there underground mining dewatering pumps play a critical role.

Dewatering Pumps for Mining Industry: Functionality and Types

Dewatering slurry pumps for mining operations are specially designed to handle abrasive fluids and work continuously in harsh conditions. There are different pumps used in water removal based on applications.

-

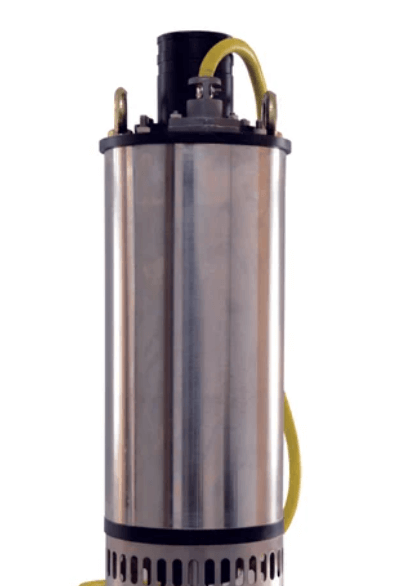

Submersible mining pumps for dewatering:

As the mining sites are usually below ground level; there is a tendency for water accumulation. Therefore, the majority of industrial mine dewatering pumps in mines are submersible pumps. You can find either an electric motor or a diesel engine-driven submersible pump immersed in the water pumping water. In addition to their adaptability to different water conditions, submersible mining pumps come in a wide range of sizes and capabilities.

Submersible pumps for dewatering

-

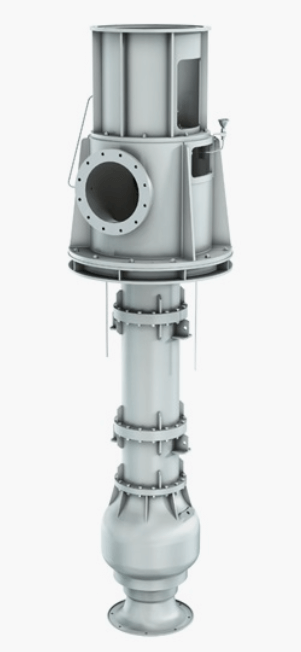

Vertical turbine pumps for dewatering:

Due to the powerful output and high efficiency, mines also frequently use vertical turbine pumps. They are either electric or diesel-powered dewatering pumps for mining, normally installed on a platform above the water. Pumping large quantities of water with a high sediment content is not a problem for vertical turbine pumps.

Vertical turbine pumps for dewatering

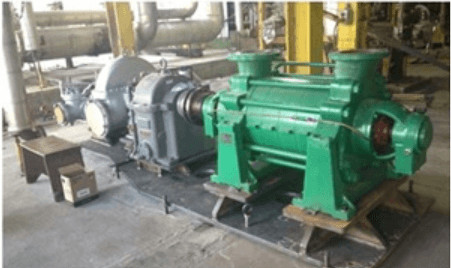

- Horizontal multistage centrifugal industrial dewatering pumps:

When water needs to be pumped over a long distance or up to a high elevation, horizontal multistage centrifugal industrial dewatering pumps are utilized in mines. These pumps are powered by either an electric motor or a diesel engine and are often installed on a platform that extends out over the water.

Horizontal multistage centrifugal pumps for dewatering

- Piston pumps for dewatering:

Piston pumps use reciprocating pistons to pump water, making them suitable for deep mining applications. They can handle high pressures and are often used in underground mines where significant water inflow is present.

Advantages of using dewatering pumps in mining sites

Mine dewatering pumps provide several advantages in the mining business. Here are some of the advantages:

Prevention of Flood and Waterlogging: When used in mines, mine dewatering pumps can remove water from the mine before it can cause flooding. Such pumps are highly powerful and run continuously without major issues. This ensures the miner’s safety and avoids any damage to the infrastructure.

Ensure a Dry Work Environment: Industrial dewatering pumps help to keep the area dry. With the help of dewatering pumps, mines can be made more workable by eliminating the presence of water. As a result, the working conditions in the mine are improved.

Improve Ventilation: Removing water with mine dewatering pumps is one way to enhance mine ventilation. Better airflow can help to reduce the risk of miners developing health problems due to exposure to harmful gases and dust.

Equipment Protection: Water accumulation can damage mining equipment and machinery, leading to costly repairs or replacements. Industrial dewatering pumps prevent water from entering critical machinery, extending its lifespan and reducing maintenance costs.

Environmental Sustainability: Proper water management in mining operations is essential for minimizing the environmental impact. Mine dewatering pumps help prevent the release of contaminated water into nearby ecosystems, ensuring compliance with environmental regulations.

Water Access to Mining Sites: Mine dewatering pumps also provide access to water for miners. The equipment pump clean water to the mining sites, where the water can be used for drinking, washing, and other purposes.

Why are Dae Pumps the Best Solution to Mining Dewatering?

DAE Pumps are specialized and designed to handle slurry and high-particle fluids that are generated in mines. The patented technology of the organization delivers high-quality products that run continuously without much maintenance. The non-clogging pump models handle slurries and debris efficiently. As an alternative to a pipeline, these machines can carry sediment to distant disposal locations by pumping dense slurries across great distances.

Final Words

To keep the mining workplace safe and to avoid any interruption in the continuous mining process, mine or industrial dewatering pumps are essential. As water removal from mines needs special machines, you need to consider several points before selecting such pumps. Pumps from the DAE brand offer a wide array of designs based on your requirements and applications.

For any requirement of a dewatering pump for the mining industry, call DAE Pumps at (760) 477-4224. You can also contact us for a free sales quote.

Frequently asked questions about industrial dewatering pumps in mining

FAQ-1: How do dewatering pumps for mining differ from dewatering pumps used in other industries?

Mine dewatering pumps differ from dewatering pumps used in other industries primarily due to the unique challenges and requirements specific to mining operations. Here are some key differences:

- Robust construction

- Handling high flow rates

- Capability to handle abrasive materials

- Submersible capability

- Integration with mine control systems

FAQ-2: What are the key factors to consider when selecting dewatering pumps for mining applications?

When choosing a dewatering pump for a mine, it’s important to consider other parameters. Below are some key factors to be considered

- The depth of the water to be pumped.

- The capacity of the pump

- The type of water to be handled

- The availability of power supply,

- Ambient temperature

- Cost

FAQ-3: What are the advantages of centrifugal dewatering pumps in mining operations?

Centrifugal dewatering pumps are widely used in mining operations for efficient water removal. These pumps offer several advantages, making them the preferred choice in the mining industry. Here are some key benefits:

- High efficiency

- Robust construction:

- Ease of installation and operation:

- Low maintenance requirements

FAQ-4: Are there specific regulations or safety considerations for industrial dewatering pumps in the mining industry?

Yes, there are specific safety regulations and safety precautions that the mining industries need to consider strictly. Here are some important aspects to consider:

- Regulatory compliance with local, regional, and national regulations

- Mine Safety and Health Administration (MSHA) standards

- Risk assessments and hazard mitigation

- Environmental considerations

- Training and competency in awareness of potential hazards, emergency procedures, and proper use of personal protective equipment (PPE).