The importance of efficient and effective dredging machines cannot be overstated today. These powerful machines are vital for maintaining waterways, preventing flooding, and supporting construction projects in aquatic environments. Dredging is a complex task that requires precision, reliability, and advanced technology to achieve the desired results. This is where DAE Pumps stands out as a leader in the field.

With years of experience and a commitment to innovation, DAE Pumps has established itself as a premier provider of dredging solutions. The company’s expertise in manufacturing and renting dredge machines and pumps is unparalleled, making them the go-to choice for industries that demand the best. Whether for large-scale dredging operations or specialized tasks, DAE Pumps delivers superior performance and reliability.

This blog delves into why DAE Pumps’ dredging machines are the best in the market. We’ll explore the critical aspects that set them apart, including their technological advancements, robust construction, and exceptional customer support. By the end, you’ll understand why DAE Pumps is synonymous with excellence in the dredging industry and how their dredge pump rentals and equipment can meet your every need.

Cutting-Edge Dredging Machines Technology

Overview of DAE’s Innovative Dredging Machine Designs

DAE Pumps has revolutionized the dredging industry with its innovative dredging machine designs. Their commitment to developing cutting-edge technology ensures that each dredge machine is built to deliver unmatched performance, durability, and efficiency. DAE machines are engineered to handle the most challenging dredging environments, providing reliable solutions for various applications.

Key Technological Advancements and Unique Features

DAE Pumps incorporates several critical technological advancements and unique features into their dredging machines, setting them apart from competitors:

- Advanced Pump Technology: Every DAE dredging machine has a high-performance dredge pump at its heart. These pumps are designed to handle abrasive materials and maintain high efficiency, even under extreme conditions. They are built with wear-resistant materials, ensuring a longer lifespan and reduced maintenance costs.

- Modular Design: DAE’s dredging machines feature a modular design, allowing for easy customization and scalability. This flexibility enables users to adapt the dredge machine to specific project requirements, enhancing efficiency and reducing downtime.

- Remote Monitoring and Control: Incorporating state-of-the-art remote monitoring and control systems, DAE dredging machines allow operators to oversee and adjust operations from a distance. This technology improves safety, reduces operational costs, and ensures optimal performance.

- Energy Efficiency: DAE Pumps prioritizes energy efficiency in their designs. Their dredging machines have energy-efficient motors and hydraulic systems that minimize fuel consumption and environmental impact.

- Innovative Cutterheads and Suction Systems: DAE’s drifting machines have advanced cutter heads and suction systems that enhance the efficiency of material extraction. These systems are designed to handle various sediments and debris, ensuring thorough and effective dredging.

Benefits of Using Advanced Dredging Machines in Various Industries

Utilizing advanced dredging machines from DAE Pumps offers numerous benefits across various industries:

- Improved Operational Efficiency: The cutting-edge technology integrated into DAE’s dredge machines ensures faster and more efficient operations. This efficiency translates into cost savings and timely project completions, which are critical in the construction, mining, and environmental management industries.

- Enhanced Durability and Reliability: DAE dredging machines’ robust construction and high-quality materials guarantee long-lasting performance. Industries benefit from reduced downtime and maintenance costs, ensuring continuous operations and better ROI.

- Versatility: DAE’s dredging machines are designed to handle various tasks, from clearing waterways to mining operations. This versatility makes them ideal for diverse applications, allowing industries to use the same equipment for multiple projects.

- Environmental Protection: DAE Pumps’ advanced dredging machines are engineered to minimize environmental impact. Their energy-efficient systems and precise dredging capabilities help protect aquatic ecosystems while meeting regulatory requirements.

- Safety: The incorporation of remote monitoring and control systems enhances the safety of dredging operations. Operators can manage the dredge machines from a safe distance, reducing the risk of accidents and improving overall workplace safety.

DAE Pumps’ Innovative dredging machine designs, key technological advancements, and unique features make their equipment the best in the market. Industries that rely on dredging operations can significantly benefit from the superior performance, durability, and efficiency of DAE’s Advanced dredging machines. Whether you need a reliable dredge pump or a comprehensive dredge machine rental solution, DAE Pumps provides the expertise and technology to meet your needs.

Comprehensive Dredging Machine Solutions

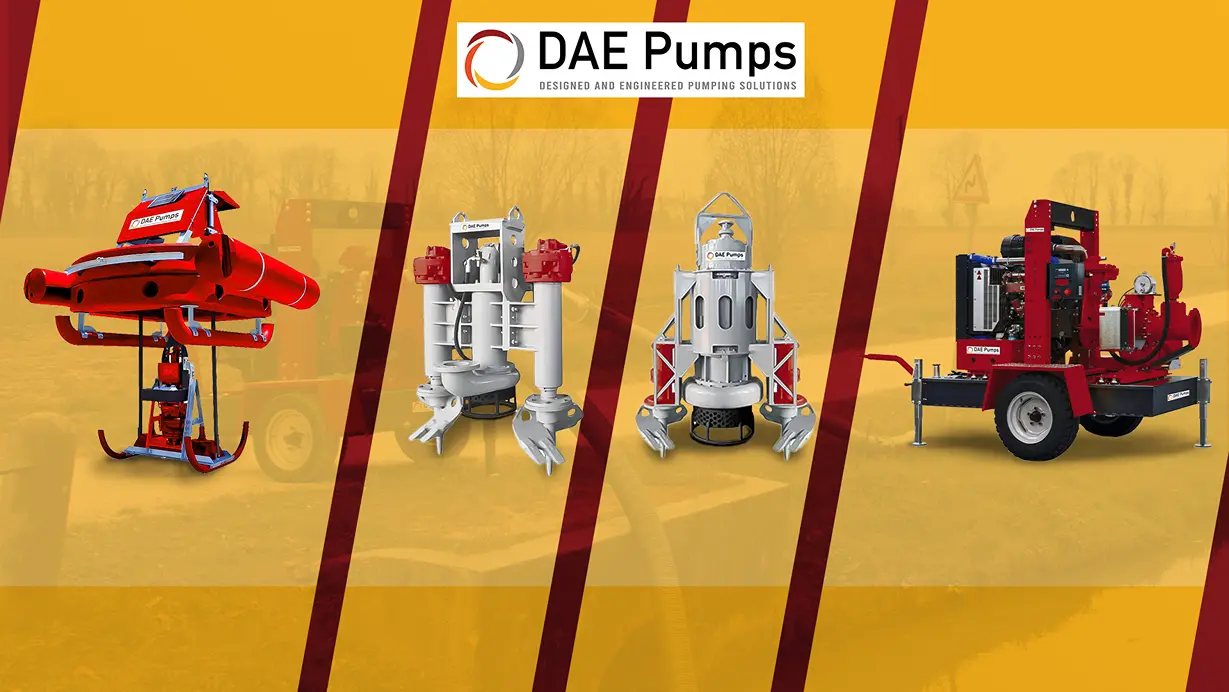

Types of Dredging Machines Compatible with DAE Dredge Pumps

DAE Pumps offers various dredging machines designed to cater to multiple dredging needs. Every dredging machine is compatible with DAE’s high-performance pumps, ensuring optimal functionality and efficiency. Here are some of the primary types of dredging machines:

- Cutter-suction dredgers: These machines have a rotating cutter head to break up hard materials on the seabed before suctioning the sediment. DAE’s dredge pumps efficiently transport the dredged material through pipelines.

- Auger Dredgers: Ideal for precision dredging in confined areas, auger dredgers use a rotating auger to loosen and transport material. DAE’s drift pumps are well-suited for these machines, providing reliable suction and discharge capabilities.

- Jet Suction Dredgers: These dredgers utilize high-pressure water jets to dislodge sediment. They rely on powerful dredge pumps to handle the mixture of water and material. DAE pumps ensure consistent performance and minimal clogging.

- Plain Suction Dredgers: These straightforward dredging machines use a suction pipe to draw loose sediment. DAE’s drift pumps excel in these setups, offering robust suction power and durability.

Features and Capabilities of DAE’s Dredging Machines

DAE Pumps’ dredging machines are packed with features and capabilities that make them the best choice for various dredging operations:

- High-Efficiency Dredge Pumps: Central to every DAE dredging machine is a high-efficiency dredge pump designed to handle abrasive materials and high volumes of sediment. These pumps are built to last, reducing maintenance frequency and costs.

- Durable Construction: These machines are constructed from high-quality, wear-resistant materials. This durability ensures long-term performance in harsh environments, including those that include saltwater and abrasive sediment.

- Modular Design: DAE’s modular dredging machines allow for easy customization and upgrades. This flexibility ensures that the equipment can be tailored to specific project requirements, enhancing operational efficiency.

- Advanced Control Systems: DAE dredging machines have sophisticated control systems for precise operation. These systems can be remotely monitored and controlled, improving safety and efficiency on-site.

- Energy-Efficient Operation: DAE’s drifting machines are designed with energy efficiency in mind. They minimize fuel consumption and environmental impact, making them a sustainable choice for dredging projects.

Integration of Dredge Pumps and Dredging Machines for Optimal Performance

The seamless integration of dredge pumps and machines is crucial for achieving optimal performance in dredging operations. DAE Pumps excels in this integration, ensuring that their dredge pumps and machines work harmoniously to deliver the best results.

- Customized Solutions: DAE Pumps offers customized dredge machine solutions that perfectly match their dredge pumps. This tailored approach ensures compatibility and maximizes efficiency in dredging operations.

- Synergistic Design: DAE’s dredging machines and dredge pumps have synergistic designs. This means that the pumps and machines are engineered to complement each other, resulting in smoother operations and reduced wear and tear.

- Enhanced Performance: DAE’s High-Performance dredge pumps are integrated with its advanced dredging machines to improve overall performance. The pumps’ powerful suction and discharge capabilities and the machines’ efficient material handling features ensure that dredging projects are completed swiftly and effectively.

- Ease of Maintenance: DAE Pumps’ integrated systems are designed for easy maintenance. The compatibility between dredge pumps and machines simplifies maintenance, reducing downtime and extending the equipment’s lifespan.

- Versatile Applications: Whether you need a dredge pump rental for a short-term project or a permanent solution, DAE’s integrated systems offer versatility for various applications. From mining and construction to environmental management, their dredging machines and pumps provide reliable and efficient performance.

DAE Pumps provides comprehensive dredging machine solutions, including various machine types compatible with high-performance dredge pumps. The advanced features and capabilities of DAE’s Dredging machines, combined with the seamless integration of their pumps, ensure optimal performance and efficiency in any dredging operation. Whether you’re looking for a dredge machine or a dredge pump rental, DAE Pumps has the expertise and technology to meet your dredging needs.

Superior Suction Dredge Performance

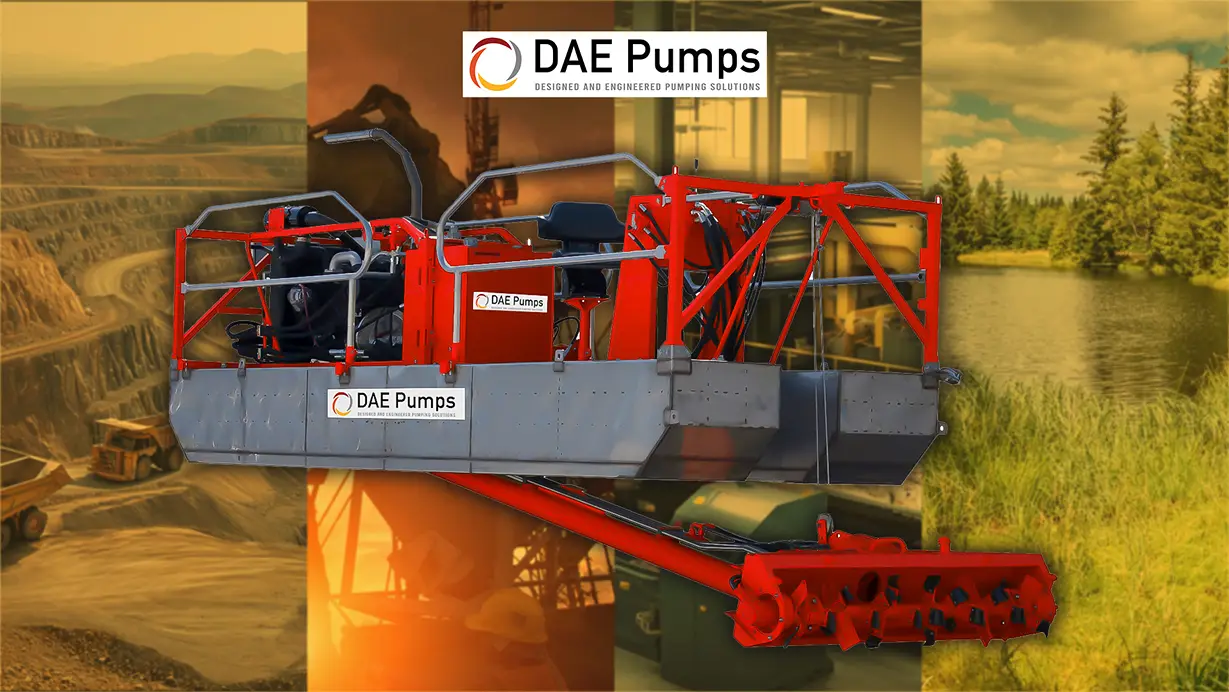

Design and Engineering Excellence of DAE’s Dredging Machines

DAE Pumps’ dredging machines are renowned for their superior design and engineering excellence. Every aspect of these machines is meticulously crafted to ensure peak performance, durability, and reliability. Key elements of their design and engineering include:

- Robust construction: dredging machines are built with high-quality, wear-resistant materials that can withstand harsh conditions and abrasive materials. This robust construction ensures a longer lifespan and reduced maintenance costs.

- Precision Engineering: The machines are engineered precisely to handle various dredging tasks efficiently. Each component, from the cutter head to the discharge pipeline, is designed to optimize performance and ensure seamless operation.

- Advanced Hydraulic Systems: DAE’s drifting machines feature state-of-the-art hydraulic systems that provide robust and reliable operation. These systems enhance efficiency and allow for precise control over the dredging process.

- Innovative Pump Design: DAE’s innovative dredge pump design is central to the performance of its Dredge machines. These pumps are designed to handle high volumes of sediment and abrasive materials without compromising efficiency or reliability.

Operational Efficiency and Effectiveness in Various Applications

DAE Pumps’ dredging machines are known for their operational efficiency and effectiveness across various applications. Their design and engineering excellence translate into several vital benefits:

- High Throughput: DAE’s dredging machines can handle large volumes of sediment quickly and efficiently, making them ideal for large-scale dredging projects. This high throughput reduces project timelines and costs.

- Versatile Applications: These machines are versatile enough for various industries, including construction, mining, environmental management, and more. Whether maintaining waterways, mining minerals, or restoring wetlands, DAE’s Dredging machines deliver reliable performance.

- Energy Efficiency: DAE’s drifting machines are designed for energy efficiency. They consume less fuel and power, reducing operational costs and environmental impact. This efficiency makes them a cost-effective choice for long-term projects.

- Precision and Control: DAE’s drifting machines’ advanced control systems allow for precise operation, ensuring that dredging tasks are completed accurately and efficiently. This precision is crucial in sensitive environments where careful material handling is required.

Case Studies Demonstrating the Successful Use of DAE Dredging Machines

DAE Pumps’ drifting machines have a proven track record of success in various projects worldwide. Here are a few case studies that highlight their superior performance:

Port Expansion Project:

DAE’s cutter suction dredgers deepened and widened the harbor in a major port expansion project. The machinery’s robust construction and powerful dredge pumps efficiently removed large volumes of sediment, completing the project on schedule and within budget.

Environmental Restoration:

A wetland restoration project requires carefully removing contaminated sediments. DAE’s auger dredgers, equipped with precision control systems, dredged the area without disturbing the surrounding ecosystem. The project was a success, restoring the wetland to its natural state.

Mining Operations:

DAE’s jet suction dredgers proved indispensable in mining operations that extract valuable minerals from a riverbed. The high-pressure water jets and efficient dredge pumps enabled the rapid and effective extraction of materials, significantly boosting productivity and reducing operational costs.

Flood Control:

In a flood-prone area, DAE’s Plain suction dredgers were used to remove accumulated sediment from riverbeds and canals. The machines’ high throughput and reliability ensured that waterways were cleared quickly, mitigating the risk of flooding and protecting the local community.

DAE Pumps’ drifting machines exemplify design and engineering excellence, operational efficiency, and effectiveness across various applications. Their innovative features, robust construction, and advanced technology ensure superior suction dredge performance. These attributes and successful case studies demonstrate why DAE’s dredging machines and pump rentals are the best for any dredging project. Whether for large-scale infrastructure projects, environmental restoration, or industrial applications, DAE Pumps delivers unmatched performance and reliability.

Key Applications of DAE Dredging Machines

Industrial Applications

DAE pumps ‘dredging machines are crucial in various industrial applications, providing reliable and efficient solutions for demanding environments. Here are some critical industrial uses:

- Mining: Dredging machines extract valuable minerals from riverbeds, ponds, and other water bodies in the mining industry. DAE’s cutter and jet suction dredgers are particularly effective for this purpose. Their powerful dredge pumps and advanced suction systems ensure the efficient extraction of minerals while minimizing environmental impact.

- Construction: Dredging machines are essential in the construction industry for land reclamation, foundation preparation, and port construction. DAE’s dredge machines remove sediments and debris, creating a stable base for construction projects. Their modular design allows customization to meet specific project requirements, enhancing operational efficiency.

- Industrial Waste Management: DAE dredging machines are also used in industrial waste management to clean up ponds, lagoons, and other containment areas. Their robust construction and high-efficiency pumps enable them to handle abrasive and hazardous materials, ensuring safe and effective waste removal.

Environmental Applications

DAE Pumps’ dredging machines are integral to various environmental applications, contributing to ecosystem restoration and waterway maintenance:

- Wetland Restoration: Wetlands are vital ecosystems that require regular maintenance and restoration. DAE’s auger and plain suction dredgers are ideal for wetland restoration projects. These machines can precisely remove contaminated sediments without disturbing the surrounding environment, helping to restore wetlands to their natural state.

- Waterway Maintenance: Maintaining clear and navigable waterways is essential for transportation, flood prevention, and environmental health. DAE’s dredging machines remove accumulated sediments, debris, and vegetation from rivers, canals, and harbors. This maintenance helps prevent flooding, ensures safe navigation, and supports aquatic ecosystems.

- Lake and Pond Rehabilitation: Over time, lakes and ponds can accumulate sediments and pollutants, affecting water quality and aquatic life. DAE’s dredging machines, equipped with advanced suction and discharge systems, clean and rehabilitate these water bodies. This process improves water quality, restores habitats, and enhances recreational opportunities.

Custom Solutions for Unique Dredging Challenges

DAE Pumps excels in providing custom solutions for unique dredging challenges. Their expertise and innovative technology allow them to address specific needs and complex projects effectively:

- Tailored Equipment: DAE offers customized dredging machines designed to meet the specific requirements of unique dredging projects. Whether it’s a specialized cutter head for a particular sediment type or a modified dredge pump for increased capacity, DAE can provide tailored solutions that ensure optimal performance.

- Dredge Pump Rentals: DAE offers dredge pump rentals for short-term or specialized projects. These rentals provide flexibility and cost savings, allowing clients to access high-quality equipment without needing long-term investment. DAE’s rental options include a variety of dredge pumps and machines, ensuring that clients can find the right equipment for their specific needs.

- Innovative Problem-Solving: DAE’s engineering team is skilled at developing creative solutions for unique dredging challenges. Whether working in difficult-to-access areas, handling exceptionally abrasive materials, or meeting stringent environmental regulations, DAE’s Dredging machines are designed to overcome these obstacles and deliver successful outcomes.

- Integrated Systems: DAE provides integrated dredging systems that combine dredge machines with ancillary equipment such as pipelines, boosters, and monitoring systems. These integrated solutions ensure seamless operation, improved efficiency, and reduced downtime, making them ideal for complex dredging projects.

DAE Pumps’ dredging machines are versatile and efficient tools for various applications. From industrial uses in mining and construction to environmental applications in wetland restoration and waterway maintenance, DAE’s dredge machines deliver exceptional performance. Their ability to provide custom solutions and dredge pump rentals further enhances their appeal, making DAE Pumps the go-to provider for all dredging needs. Whether tackling everyday dredging tasks or addressing unique challenges, DAE’s innovative technology and expertise ensure the best possible results.

Maintenance and Reliability of DAE Dredging Machines

Importance of Regular Maintenance for Dredging Machines

Regular maintenance ensures dredging machines’ longevity, reliability, and optimal performance. These machines operate in harsh environments, handling abrasive materials and encountering challenging conditions. Proper maintenance allows components to wear out quickly, leading to decreased efficiency, unexpected breakdowns, and increased operational costs. Ensuring that dredging machines receive regular upkeep minimizes downtime, extends equipment lifespan, and guarantees consistent, high-quality performance.

DAE’s Recommended Maintenance Practices

DAE Pumps is committed to helping customers maintain their dredging machines in top condition. They recommend the following maintenance practices to ensure the reliability and efficiency of their equipment:

- Daily Inspections: Conduct visual inspections to check for any signs of wear, damage, or leaks. Pay special attention to hoses, fittings, and seals, as these components are prone to wear and tear.

- Lubrication: Regularly lubricate all moving parts according to the manufacturer’s guidelines. Proper lubrication reduces friction and wear, ensuring smooth operation and extending the lifespan of components.

- Pump Maintenance: Inspect dredge pumps frequently for signs of wear, especially the impeller and casing. Replace worn parts promptly to maintain optimal pumping efficiency and prevent further damage.

- Hydraulic System Check: Regularly check the hydraulic system for leaks, pressure drops, and contamination. Clean or replace hydraulic filters as needed to ensure the system operates efficiently.

- Cutterhead and Auger Maintenance: Inspect the cutter head or auger of cutter suction and auger dredgers for wear and damage. Replace or repair damaged components to maintain effective sediment removal.

- Electrical System Inspection: Inspect the electrical system for loose connections, corrosion, and damaged wiring. Ensure that all sensors and control systems are functioning correctly.

- Cleaning: After each operation, clean the dredging machine thoroughly to remove sediment, debris, and other contaminants. This prevents build-up that can cause corrosion and other damage over time.

Tips for Troubleshooting Common Dredging Machine Issues

Even with regular maintenance, dredging machines may occasionally experience issues. Here are some tips for troubleshooting common problems:

- Reduced Pump Performance: If the dredge pump is not performing optimally, check for blockages in the suction line or pump casing. Inspect the impeller for wear or damage and replace it if necessary. Ensure the pump is primed correctly and the system has no air leaks.

- Hydraulic System Issues: If the hydraulic system is not functioning correctly, check for leaks, low fluid levels, or contaminated fluid. Inspect hoses and connections for damage or wear. Ensure the hydraulic pump and motors operate within the specified pressure range.

- Electrical Problems: If the electrical system has issues, check for blown fuses, tripped circuit breakers, or loose connections. Inspect the wiring for signs of wear or damage. Test sensors and control systems to ensure they are functioning correctly.

- Cutterhead or Auger Malfunctions: If the cutter head or drill is not operating effectively, inspect it for wear or damage. Replace worn or damaged teeth or blades. Ensure that the drive mechanism is functioning correctly and that there are no obstructions in the cutter head or auger housing.

- Unusual Noises or Vibrations: If the dredging machine is making unusual noises or vibrations, inspect all moving parts for signs of wear or damage. Check for loose bolts or connections. Ensure that all components are correctly aligned and balanced.

- Fuel Efficiency Issues: If the machine consumes more fuel than usual, check the engine and fuel system for leaks, clogs, or other issues. Ensure that the engine is tuned correctly and that all filters are clean.

Regular maintenance is essential for the reliability and longevity of DAE’s drifting machines. Following DAE’s recommended maintenance practices and addressing issues promptly, operators can ensure their dredge machines operate efficiently and effectively. For those utilizing dredge pump rentals, adhering to these maintenance tips is equally important to maximize the performance and lifespan of the rented equipment. Maintaining your dredging machine for industrial or environmental applications ensures consistent, high-quality results and minimizes downtime and operational costs.

Conclusion

DAE Pumps has established itself as a leader in the dredging industry through its technological superiority and commitment to innovation. From advanced dredging machine designs and state-of-the-art dredge pumps to comprehensive maintenance and support services, DAE Pumps delivers unmatched performance and reliability. Their machines are engineered to handle the most demanding environments, ensuring efficient and effective operations across various industries, including mining, construction, and environmental management.

Choosing the suitable dredging machine for your needs involves considering several factors, such as the specific requirements of your project, the type of materials you will be handling, and the operating conditions. DAE Pumps offers various dredging machines and dredge pump rentals tailored to meet these diverse needs. Their modular designs, high-efficiency pumps, and customizable solutions ensure you have the right equipment for any dredging challenge.

When you opt for DAE Pumps, you choose cutting-edge technology, durability, and exceptional support. Whether undertaking large-scale industrial projects or delicate environmental restoration, dredging machines, and pump rentals provide the reliability and efficiency you need to achieve your goals. Trust in DAE Pumps to deliver the best dredging solutions and experience the difference that superior technology and expertise can make for your operations.