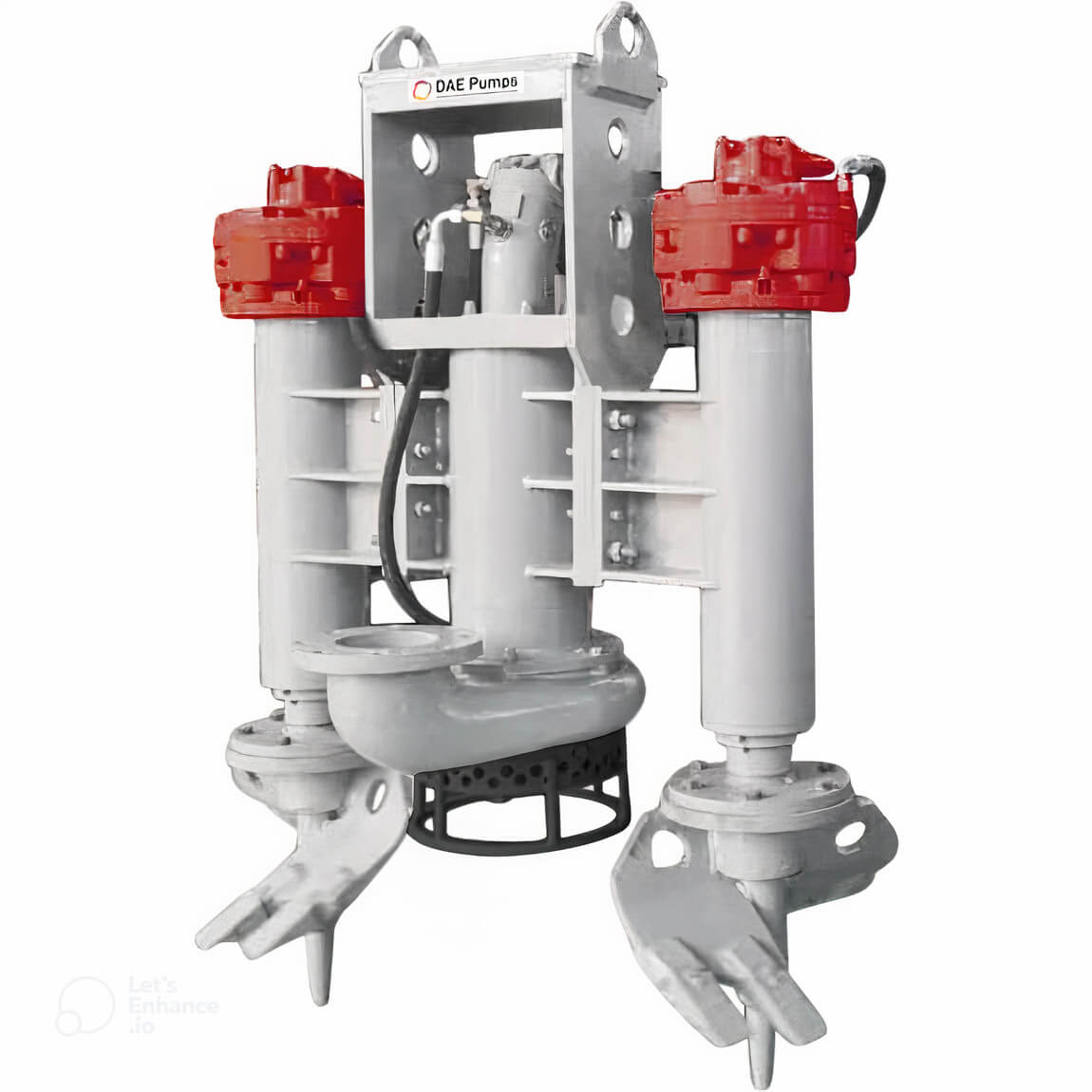

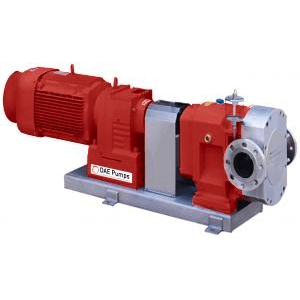

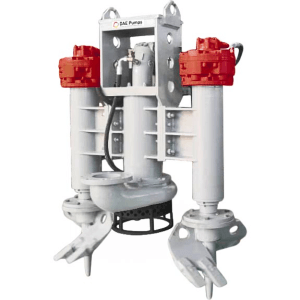

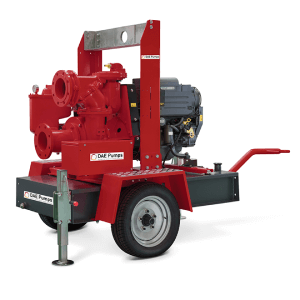

Abrasion Resistance: These Dredge Pumps are designed with wear-resistant materials and components, allowing them to handle abrasive materials such as rocks, sand, and slurry with minimal wear and tear. This ensures extended pump life and reduces maintenance requirements.

Robust Construction: DAE Dredge Pumps feature robust construction and heavy-duty components, making them well-suited for the harsh conditions encountered in dredging operations. They are built to withstand the rigors of continuous usage and challenging environments.

Durable Bearings: High-quality bearings support the rotating components, reducing friction and increasing the pump's overall reliability and lifespan.